Log Cabin Chinking

Log cabin chinking is the most important thing to keep the weather and rodents out. The cabin was built by my father-in-law in 1970. Construction is upright log. Each log was cut and hand peeled then set in place. The interior is rustic with that old cabin look and feel. Being almost 50 years old it is a constant battle to keep everything sealed. Having the logs upright means there is constant expansion and contraction from season to season. Winters can be particularly harsh with at least one month where it warms up to 20 below zero as the daily high and a constant of 40 below at night. This makes having a tightly sealed cabin even more important. Chinking is the filler for the gaps between the logs.

The cabin is literally in the middle of nowhere. It is not accessible by road. It is barely accessible with an ATV. The best time to get to the cabin is by snowmobile is in the winter. You would be amazed at how many rocks, stumps and mud holes the ice and snow covers. Living in Northern Ontario does help. Four feet of snow in the winter is normal. Winter is also the best time to bring out materials. A person can fit a lot of material in a sleigh.

Above is a picture of the cabin in the winter. Below is a picture of the cabin in the fall. My ATV is at the south end of the lake. It is a 30 minute paddle across the lake to get here. I use the 3 wheeler and a little trailer to get around at the cabin once I am here.

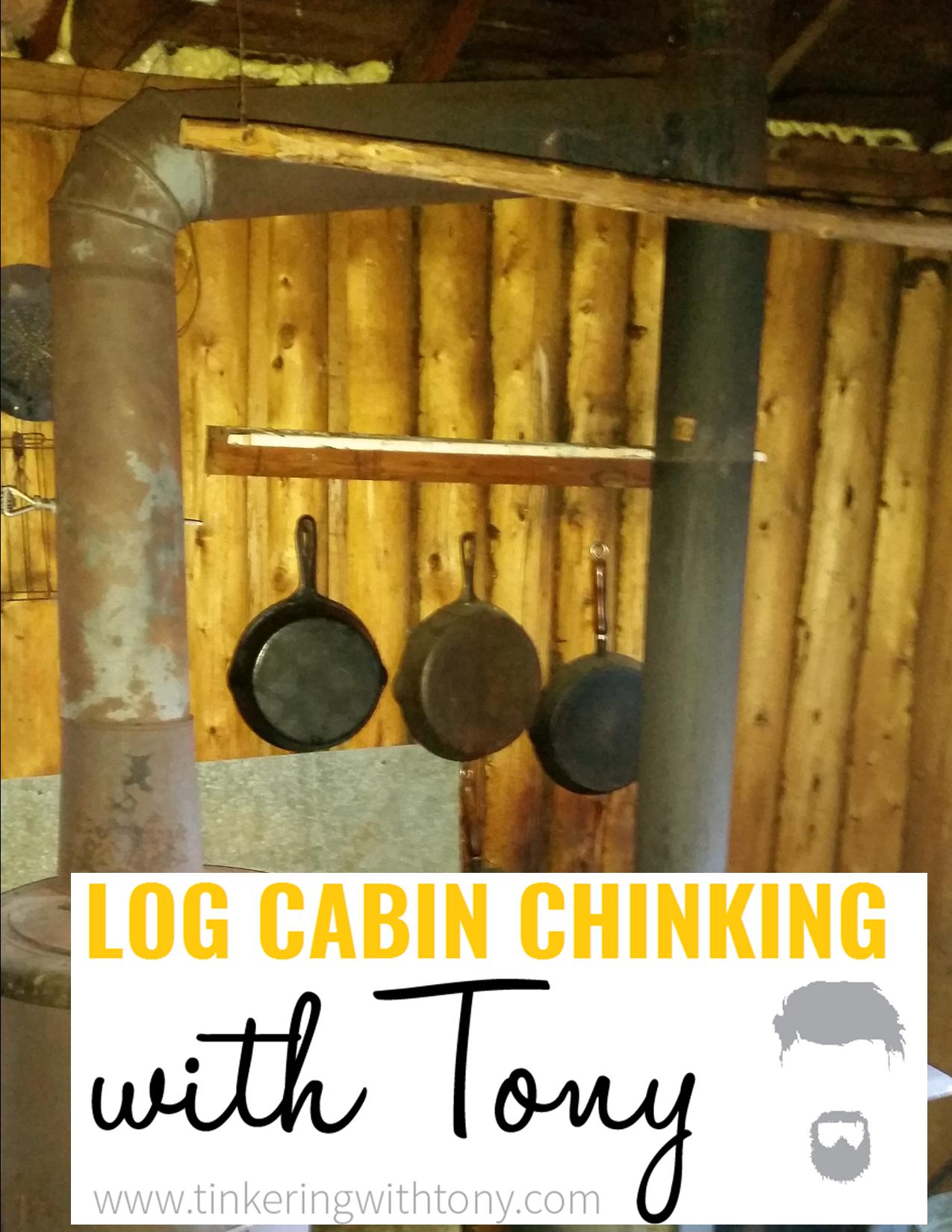

Below is a picture of the upright logs behind the stoves. Between the logs is older chinking that needs to be reset. The round stove on the left is an old coal burner that is almost 100 years old. It throws the heat really good but does not last very long. The old stove really likes to eat the wood. The stove on the right is a newer air tight stove. It will last almost all night without a refill.

After taking down the the pans and removing the heat shield you can see where the chinking has started to come out. It appears to look like an old hemp rope, just not wound as tight.

A flat head screwdriver was used to push the rope back into the gap.

2×4 were cut into triangular strips in varying sizes. These strips where then nailed into position. I used an air gun and a small compressor hooked up to a generator. There is some older wooden strips that look like they were installed when the cabin was built. Each one was nailed into place using finishing nails and a countersink. You really have to appreciate the hard work that went into building this cabin without the luxury of modern tools.

Here I am marking the length of the wooden strip to be cut.

The gaps are now nice and tight allowing very little cold air to get in.

Now that the chinking is done it will be easier to keep the cabin warm as there are no more gaps between the logs.